Real-time catalyst feed measurement

In the production of polymer resins, instantaneous and average catalyst mass flow feedback is essential for reaction rate control and high-quality production. The Correflow 6400 provides direct measurement of catalyst concentration and mass flow, enabling closed-loop process control from this critical parameter. Other methods indirectly measure only the mass flow of the slurry, not the catalyst fraction, and erroneously assume that the slurry concentration is always constant.

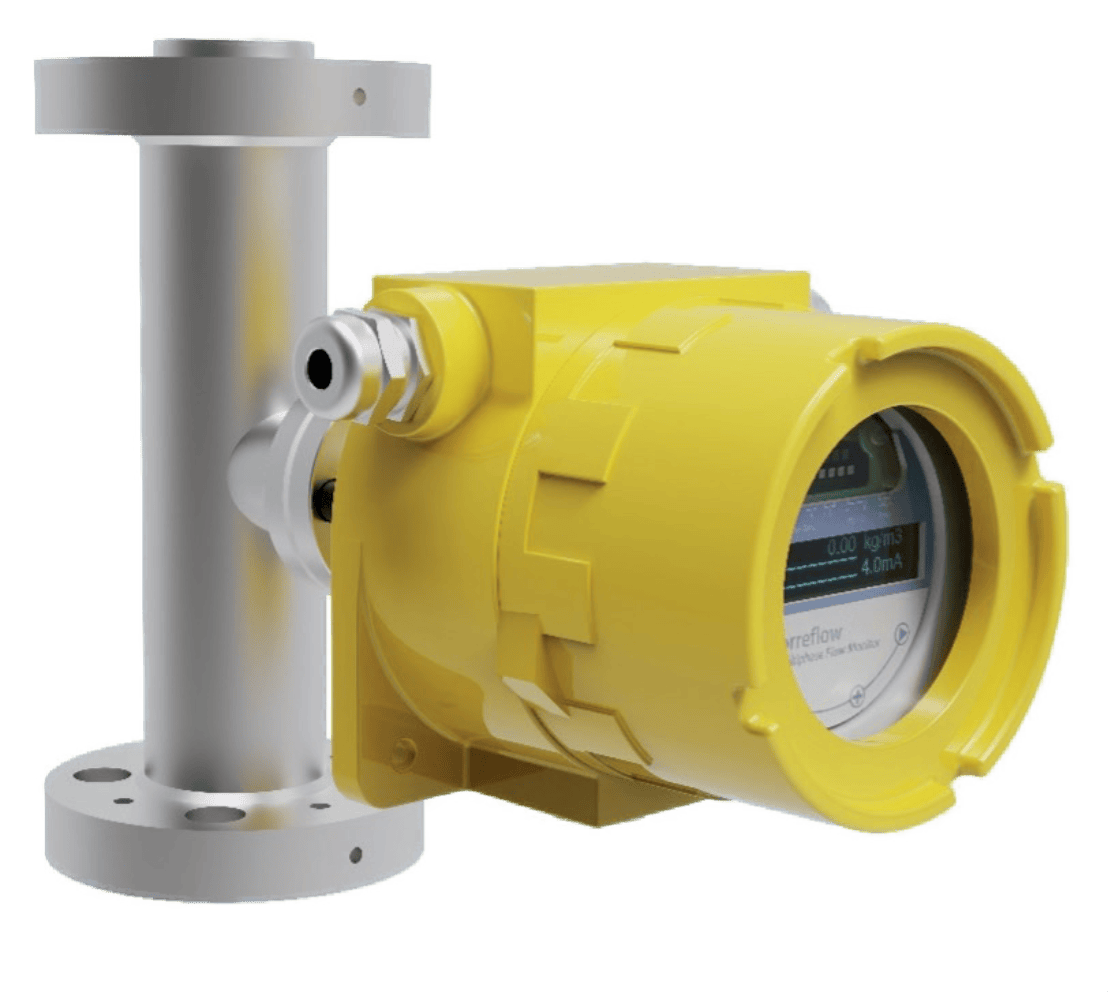

Unlike those alternatives, this in-line, real-time system directly measures velocity, concentration, and mass flow of each component in various two-phase mixtures. It works with gas, solid, or non-conducting liquid in nearly any combination of two materials. In most catalyst feed streams, it’s the only way to accurately monitor actual feed rates.

MECHANICAL

ENVIRONMENTAL:

ELECTRICAL

PERFORMANCE

DISPLAY

The Correflow 6400 is an industrialized, non-intrusive mass flow meter designed for continuous, real-time flow monitoring in demanding process environments. Leveraging advanced cross-correlation time-of-flight and capacitance tomography technologies, it delivers precise, dependable measurement of flow rate and concentration in two-phase (solid-liquid/solid-gas/liquid-gas) streams. Its robust design is ideally suited for monitoring catalyst injection rates, suspended density, and particle velocity across a variety of flow regimes.