LexMar Global delivers

Innovative industrial automation

Polyolefin reactor optimization

Quality control solutions

Benefits of Working with

World Class Service and Support

- 24/7 on-line or phone support

- Priority support for contract customers

- Remote interface and access support

Gas phase reactor continuity

- Detection of sheeting/fouling

- Elimination of agglomeration

- Shut down avoidance

Fines and dust monitoring

- Increase production output

- Optimize reaction control

- Lower maintenance cost

Sample extraction, and handling

- Fully automatic

- Representative cut of process

- Powders and pellets

Online polymer analysis

- Real-time feedback

- Closed-loop advanced process control

- Non-destructive measurements

The world's leading petrochemical companies use

products.

products.

Products

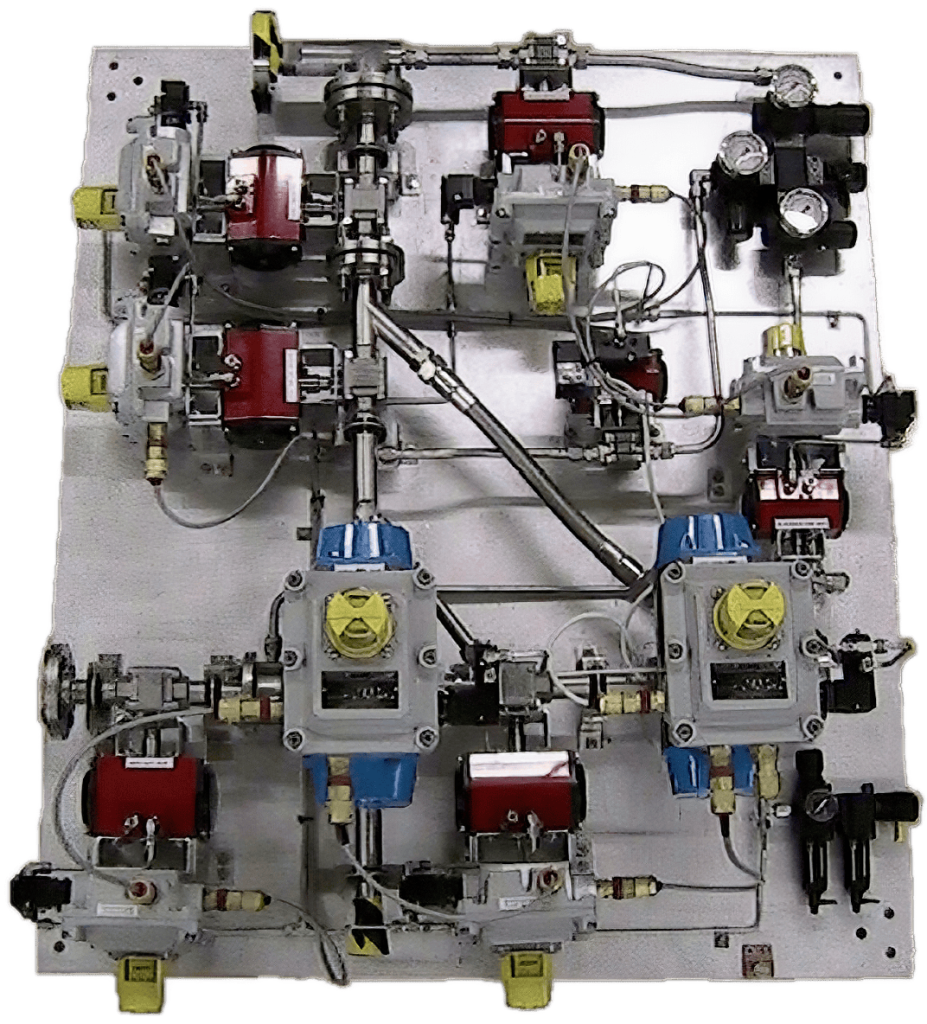

Delivers real-time, non-destructive polymer analysis with full automation and certified safety for industrial environments.

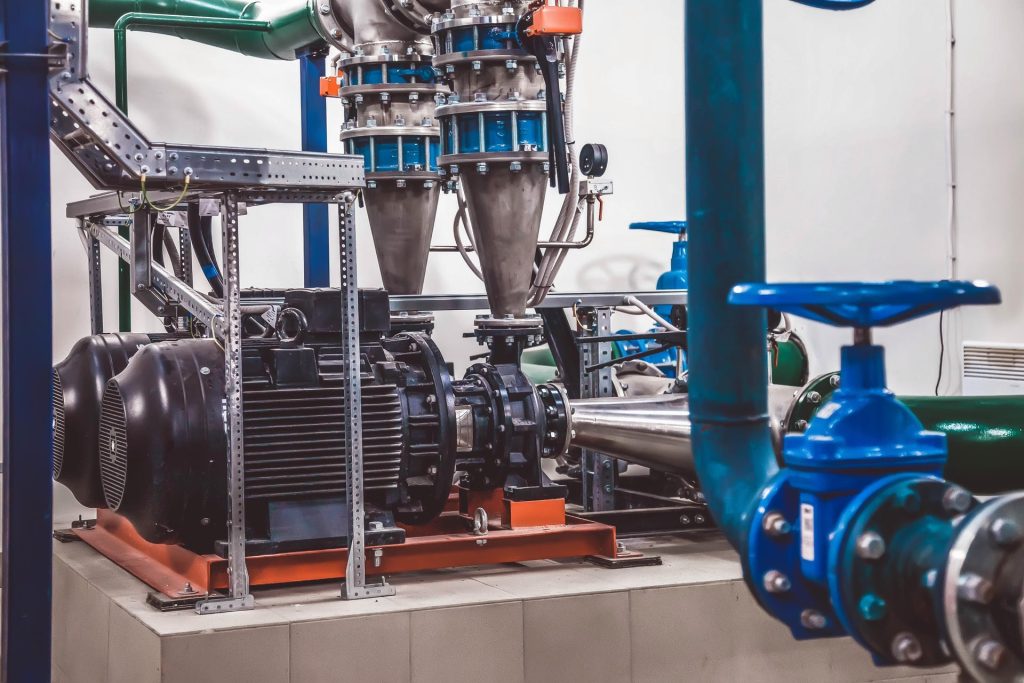

Extracts representative polyolefin samples from the production line and transfers to analyzer.

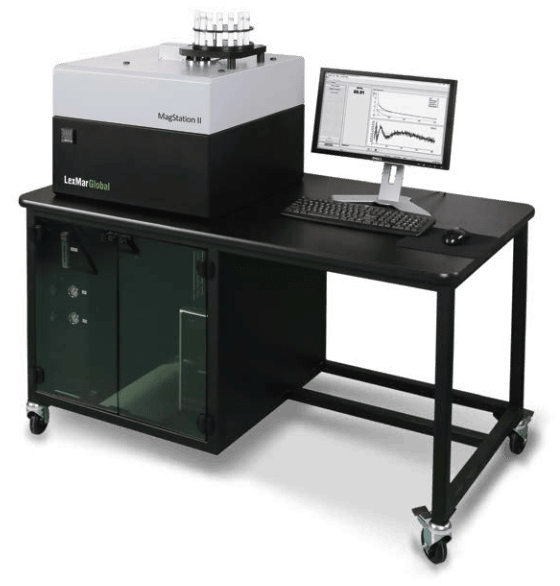

Streamlines precision polymer research and QC with automated, multi-property analysis and seamless data integration.

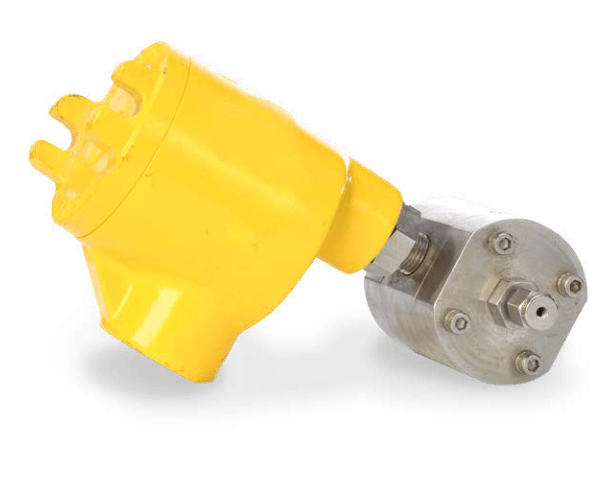

Enables real-time electrostatic monitoring to prevent agglomeration and maintain reactor stability.

Detects particle surges in gas lines, enabling real-time reactor control and protection from costly equipment damage.

Tracks real-time catalyst flow to boost process continuity and prevent reactor disruptions.

Value Proposition

LexMar Global offers a full range of support services, from 24/7 on-line or phone support to in-field technicians

Reduction in inventory Savings from on-line Mechanical Properties Analysis

Early Warning Systems help plant operators

Realtime Process Optimization leads to better Product Capability

Gas phase reactor optimization

Closed loop XS control leads to more product within target limits compared to traditional method

News & Events

Let’s Meet at K Show!

- September 23, 2025

October 8-15, 2025

Hall 10, booth E08

Maximize the potential of your polyolefin production.

Discover how our advanced technologies—such as real-time resin characterization, catalyst injection measurements, and electrostatic monitoring—can help you optimize performance, reduce variability, and elevate product quality.

LexMar Global technical and commercial experts will be at the K Show in Düsseldorf, Germany and we’d love to meet with you!