Real-time inline catalyst detection

The Correflow™ 5430 electrostatic sensor monitors conditions within polyolefin reactor catalyst feed lines. It can measure catalyst pulses and feeder changes, allowing plant operators to take appropriate actions to avoid problems.

With the real-time feedback from these electrostatic charge measurements, process continuity can be improved, and shutdowns prevented.

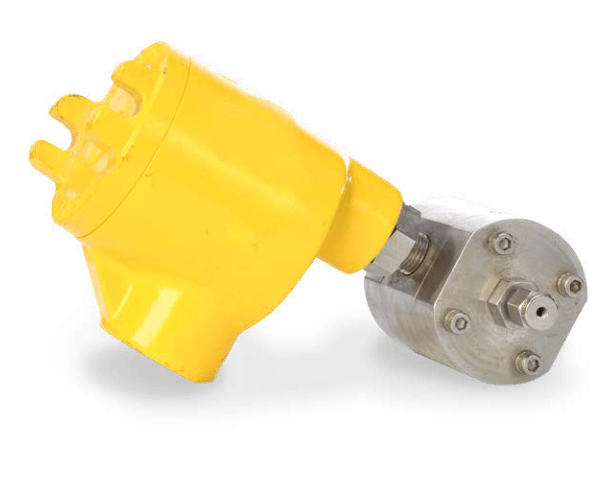

The Correflow ring sensor is installed directly in the catalyst feed line. The sensor ID can be customized to fit existing lines greater than 1/8” (3 mm). The Correflow 5430 is typically provided in a remote configuration to allow for a variety of process and mounting requirements.

MECHANICAL

ELECTRONICS ENCLOSURE

ELECTRICAL

DISPLAY

The Correflow™ 5430 sensor directly measures catalyst as it feeds into a reactor. The system provides a robust, non-contact measurement of catalyst conveyed by gas or solvent. Polymer manufacturers have substantially improved reaction control using the Correflow for instant detection of catalyst blockages or blow-by to ensure polymer production efficiency and shutdown avoidance.