Industrial Magnetic Resonance Products

LexMar Global’s Industrial Magnetic Resonance (IMR) products are state-of-the-art nuclear magnetic resonance (NMR) analyzers for industrial use. These instruments are widely used for process and quality control applications in manufacturing plants. Our method replaces traditional wet chemistry methods which are time-consuming, laborious, expensive and environmentally problematic. Whether for online or laboratory use, we customize our analyzers in multiple configurations for use in manufacturing environments. The majority of our analyzers is sold to polyolefin manufacturing plants.

The term Industrial Magnetic Resonance (IMR) refers to the use of NMR within industrial settings, typically in environments where instrumentation needs to be robust, automated, affordable as well as easily integrated and maintained. The method typically employs low-field NMR relaxometry, a.k.a. time-domain nuclear magnetic resonance (TD-NMR), but in some cases NMR signals are converted to the frequency domain.

Most customers use our analyzers to measure chemical and physical properties and composition of polyolefins. IMR is the only characterization method that can be used online within hazardous areas of PP and PE manufacturing plants, which is why it has been widely used for process and quality control applications in these plants worldwide for several decades. Applications include XS, C2 and mechanical properties (Flex Mod, Charpy/ Izod) for PP as well as density and to some degree MFR for PE. Our solutions are applicable for pellets as well as powders.

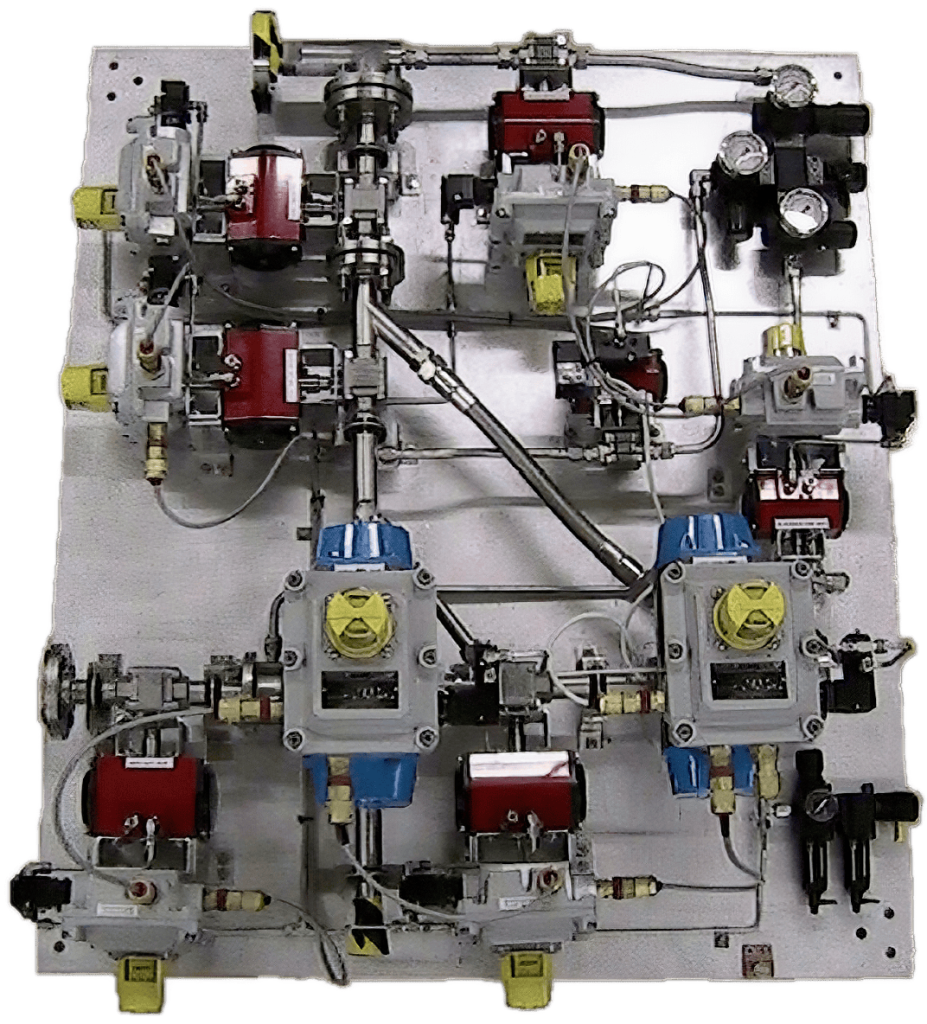

Our online analyzers (MagModule II) allow for fully automatic measurements of many properties within minutes – even in hazardous areas, for either powders or pellets. Results are automatically converted into the desired properties and can be directly reported to any kind of DCS systems.

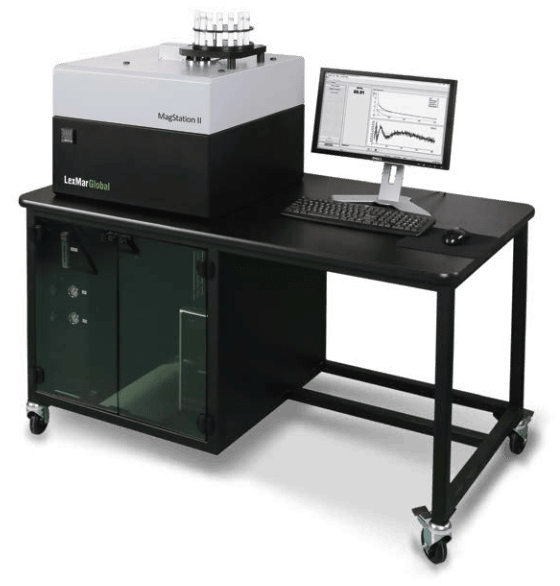

Our laboratory analyzers (MagStation II) provide off-line measurements and ensure quality control for scalable method development for powders and pellets. Properties can be measured within minutes and chemometric analysis results are reported instantly to any kind of LIMS systems, allowing for real time control.

Our proprietary A/Ztec software suite is installed on all our equipment providing an efficient user interface, data storage/ retrieval capabilities, and is configured for LIMS/DCS communications as mentioned above.

In summary, the MagModule II and MagStation II bring the latest in magnetic resonance analysis technology into industrial plant environments with worldwide support and training. Reliability and low cost of ownership are the cornerstones of our Magneflow IMR analysis product line. With more than 10 million hours of online operation, our IMR products consistently withstand the test of time.

Delivers real-time, non-destructive polymer analysis with full automation and certified safety for industrial environments.

Extracts representative polyolefin samples from the production line and transfers to analyzer.

Streamlines precision polymer research and QC with automated, multi-property analysis and seamless data integration.