SUMMARY

The global polyolefin industry produces materials which have, over the years, replaced many traditional materials such as wood, steel, and ceramics. Polyolefin plants are adapting with more advanced technology to improve efficiency, reduce transition times, and tailor products to meet the ever-increasing demand on mechanical requirements. The melt flow rate* (MFR), or simply melt flow (MF), is a measure of the flowability of a thermoplastic material and is typically expressed in grams of polymer per 10 minutes. It is a strong indicator of how suitable a material is for a given injection molding or extrusion application. The MF of a polyolefin is affected by several factors, including molecular weight and molecular weight distribution. Materials with a lower average molecular weight will typically display higher melt flow rates. MF is traditionally measured via the procedures outlined in the ASTM D1238 and ISO 1133 standards. These methods require samples to be manually collected from the process and taken to the laboratory for analysis and are therefore unsuitable for real-time process monitoring and reactor control.

MagModule™ II Industrial Magnetic Resonance (IMR) analyzers from LexMar Global Inc. provide fast, robust, and reliable solutions for the measurement of MF. LexMar Global Inc. is the world’s leading supplier for IMR technology to the polyolefin industry and is the only manufacturer of fully automated online process equipment used by the world’s most efficient polyolefin resin producers.

Global and regional competition in the polyolefin markets has in- creased significantly in recent years. The ability to consistently produce in-spec product grades, i.e., prime material, is critical for producers to maintain key customers and grow market share. The MagModule II IMR system has repeatedly demonstrated its ability to monitor resin consistency in real-time. Many customers have documented process capability index (CpK) improvements as a result of utilizing online IMR analysis of resin properties.

*alternatively referred to as Melt Flow Index (MFI) in the case of polyethylene.

PROCESS OPTIMIZATION

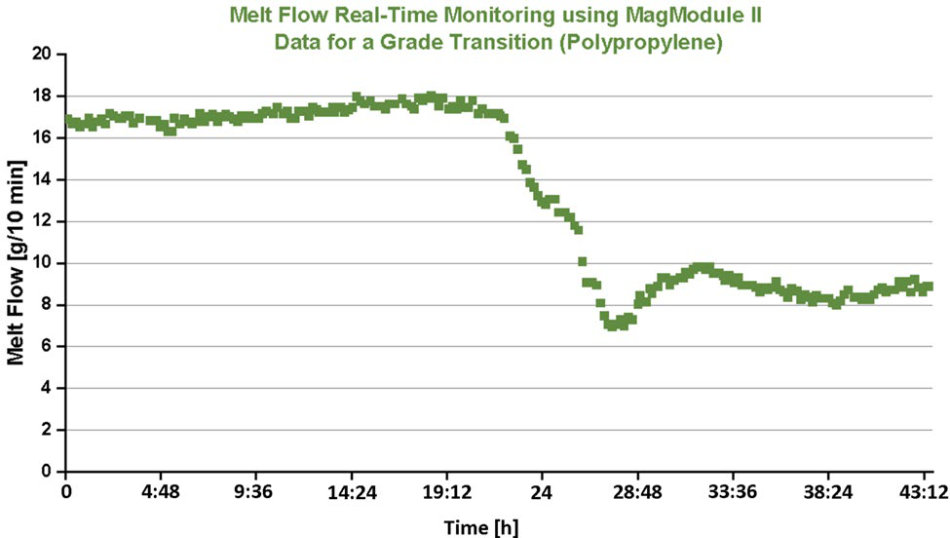

Polyethylene and polypropylene producers worldwide use the MagModule II online analyzer for real-time monitoring of melt flow rates during polyolefin production. This online IMR instrument automatically collects samples from process transfer lines every 8-10 minutes, with no human intervention required. Analysis results are transmitted directly to the plant’s DCS, giving operators immediate insights into key resin properties. This rapid feedback is especially valuable during product transitions, allowing operators to quickly reach target specifications and reduce transition waste. Additionally, the system enables fast intervention of process upsets, minimizing downtime and product loss. Ultimately, the advanced real-time control provided by the MagModule II improves reactor performance, leading to lower production costs and optimized polymer materials

PRINCIPLE OF OPERATION

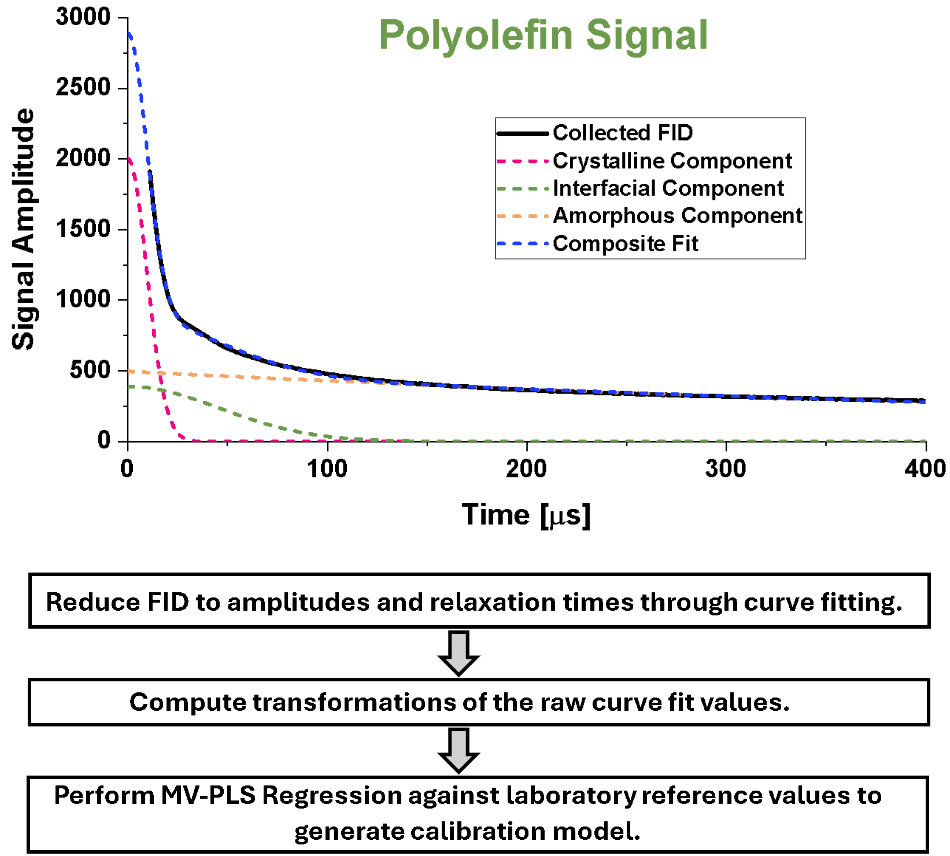

The MagModule II utilizes Magnetic Resonance (MR) technology for

the analysis of polyolefin materials. In MR, a sample is positioned within a strong magnetic field. A short radio-frequency pulse is applied to the sample which then produces a Free Induction Decay (FID) signal. This FID signal contains significant information about the morphological characteristics of the sample.

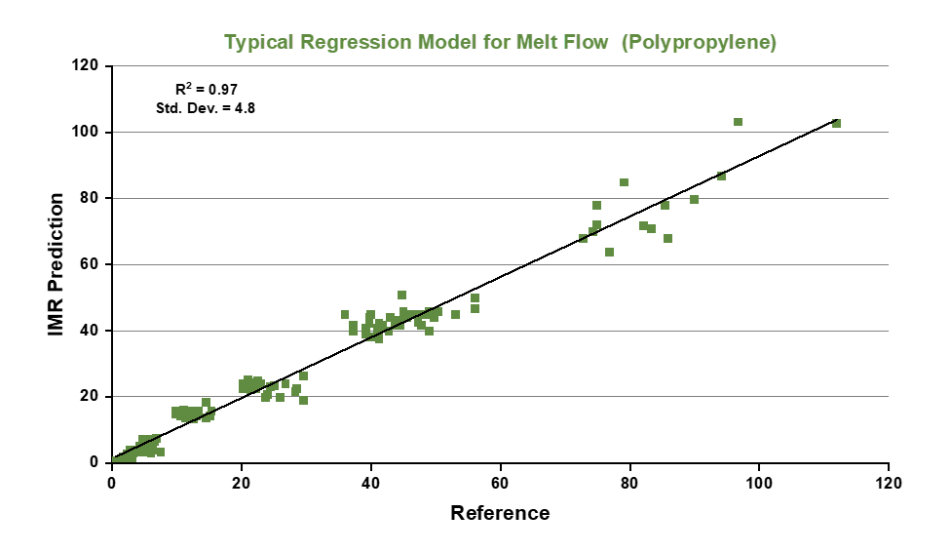

Curve fitting and multivariate regression analysis are the most effective techniques for relating the FID shapes to standard labora- tory measurements. In this approach, parameters derived from the IMR measurements, such as the amplitudes and decay time constants of the individual curve fit components, are combined with laboratory reference data to create a reliable and effective predic- tive model. Multivariate Partial Least Squares (PLS) modeling offers significant advantages over simpler single-variable linear models. PLS can incorporate and account for greater variability in product and process parameters compared to single-variable models, which typically require periodic model parameter adjustments and multiple models to cover the range of product types.

MagModule II analyzers are calibrated against traditional laboratory methods. Calibration can be performed by LexMar Global or by locally trained plant staff. The use of multivariate Principal Component Analysis (PCA) and Partial Least Squares enables the development of robust models that can be used during product transitions, as these models incorporate multiple product grades in their training datasets. Once established, calibration models are very stable and rarely require adjustments. The analysis is virtually unaffected by color, particle size, product homogeneity, or other matrix effects.

SAMPLING

For online analysis, a customized sample extraction panel

automatically collects samples as close to the reactor as possible and conveys them directly to the MagModule II system. All sample sizing

and preparation is completely automated. The entirety of the sample analyzed is returned to the process and therefore resin waste is reduced significantly.

BENEFITS & SERVICES

- Rapid and accurate MFR / MFI analysis of polypropylene and polyethylene

- Analysis of powders or pellets

- Fully automated 24/7 analysis

- Non-destructive measurement

- No necessity for sample preparation

- Simple, highly repeatable analysis

- Operator independent results

- Additive and solvent-free analysis

- Pre-loaded methods and analysis routines

- Results are fully compatible with DCS and LIMS systems

- Customized solutions for hazardous and non-hazardous zones

- Large sample volumes (25 mL) ensure proper representation for the most accurate results

FURTHER INFORMATION

Other LexMar Global polyolefin application offerings include:

- Analysis of polypropylene (PP) homo and copolymers measuring xylene solubles content (XS), ethylene content (C2), Izod/ Charpy impact strength, as well as Flexural Modulus (FM).

- Analysis of polyethylene (PE) measuring density

In addition to the MagStation™ II and MagModule™ II LexMar Global proudly offers also the following analytical equipment:

- Electrostatic Reaction Monitoring:

- Correstat™ 5410

- Correflux™ 5420

- Correflow™ 5430