SUMMARY

The global polyolefin industry produces materials which have, over the years, replaced many traditional materials such as wood, steel, and ceramics. Polyolefin plants are adapting with more advanced technology to improve efficiency, reduce transition times, and tailor products to meet the ever-increasing demand on mechanical require- ments. A key mechanical parameter is flexural modulus, the quantifi- cation of a material’s resistance to bending. Flex mod is directly rela- ted to a material’s stiffness or rigidity. This property is especially of interest for high stress or load bearing applications. It has been tradi- tionally determined by extracting the slope of the stress-strain curve generated by flex tests such as ASTM D790 or ISO 178.

However, these traditional methods require the preparation of multiple test specimens, time-consuming equipment setups, repeated analysis for accurate results, and are prone to errors due to operator dependencies.

Magneflow Industrial Magnetic Resonance (IMR) analyzers from LexMar Global Inc. provide faster, more robust, and reliable solutions for the measurement of flexural modulus.

LexMar Global Inc. is the world’s leading supplier for IMR technology to the polyolefin industry. The company provides robust laboratory instrumentation (MagStation II) and is the only manufacturer of fully automated online process equipment (MagModule II) used by the world’s most efficient polyolefin resin producers.

TECHNOLOGY OVERVIEW

The Magneflow product line utilizes Magnetic Resonance techniques in the analysis of polyolefin materials. In IMR, a sample is positioned within a strong magnetic field. The nuclei contained in the sample begin to orient into multiple population states due to the presence of this external magnetic field. This orientation yields a small net mag- netic moment. A short radio-frequency pulse is applied to the sample which rotates this magnetic moment. As it returns to equilibrium after the pulse, a Free Induction Decay (FID) signal is detected by the IMR probe. This FID signal contains information about the morphology of the material. If multiple morphological domains exist within a single sample, the FID can be modeled as the sum of multiple smaller components. For polyolefin materials, this approach allows for direct measurement of crystallinity, i.e. crystalline, amorphous and inter- facial domains within a given sample. Crystallinity is directly proportional to flex mod.

PROCESS OPTIMIZATION

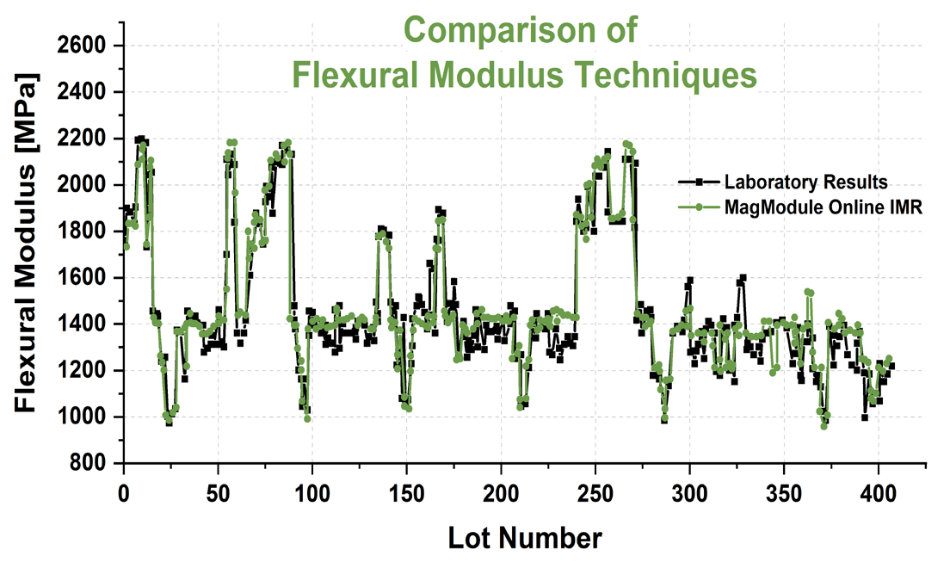

Polyethylene and polypropylene producers successfully utilize real- time feedback from the MagModule II online analyzer to continually monitor flexural modulus during the extrusion-pelletizing process. Polyolefin materials are often copolymerized to modify the impact properties of the products. These inclusions influence the flexural modulus of the final product. Producers can monitor the flexural modulus of these copolymer blends within minutes post extrusion to ensure quality standards are upheld.

CALIBRATION AND RESULTS

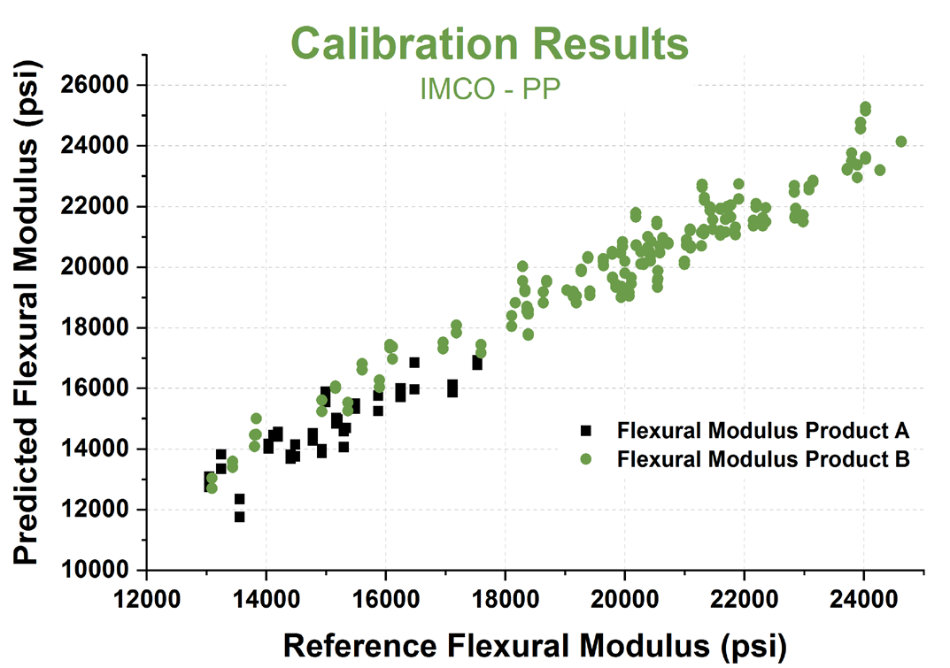

Both the laboratory and online Magneflow IMR analyzers are typically calibrated against traditional standard methods. It is the customer’s choice whether the calibration is performed by LexMar Global or lo- cally by the plant staff. Linear calibrations are easy to generate with a limited number of reference samples provided that the entire product range is represented in the sample set. The use of multivariate PCA and PLS techniques enables the generation of robust models which can even be used during product transitions as they incorporate multiple product grades in their datasets. After transitions, the MagModule II communicates with the DCS to automatically select the optimal calibration for each product grade. The calibration models, once established, are very stable, typically for years, and only in rare cases require adjustments. Fig. 2 demonstrates typical calibration performances for the Magneflow product line.

Sampling

Typically, extruded pellets are sampled from the process for Magneflow IMR analysis. For online analysis, a customized sample extraction panel automatically collects samples as close to the extruder or quenching bath as possible and conveys it directly to the MagModule II system. The entirety of the analyzed sample is returned to the process and therefore resin waste is reduced significantly. For offline IMR, samples are manually collected and loaded into state-of- the-art sample tubes, engineered to expedite sample conditioning and analysis. The samples (25 g) are analyzed using the Magneflow IMR instrument in approximately 10 minutes to provide an accurate flexural modulus prediction. No sample preparation is required and there is no need to produce custom extruded or molded test specimens. Since the Magneflow IMR technology measures 100% of the sample in the testing probe, the analysis is virtually unaffected by color, particle size, product homogeneity, or other matrix effects.

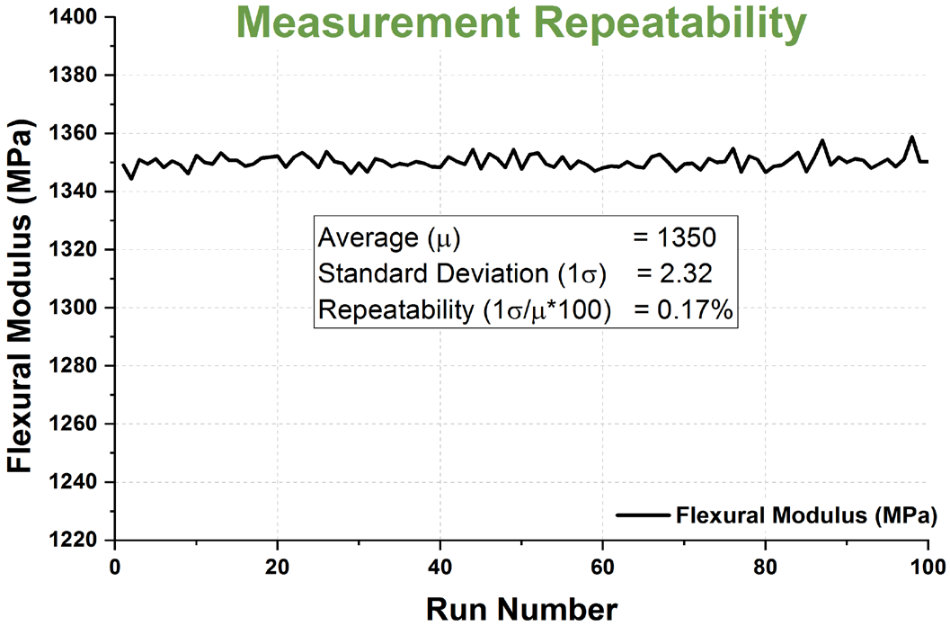

REPEATABILITY

Standard laboratory methods for Flexural Modulus measurements report repeatability errors (coefficients of variation) in the range of 3% to 13% for various products. This amount of variability is quite significant and can lead to uncertainty when optimizing blends or reporting a certificate of analysis. Magnetic resonance is well known for outstanding analytical repeatability with coefficients of variation significantly less than 1%. This precision arises from the fact that IMR is a bulk measurement technique, which means that not only the surface, but the entirety of the sample is measured simultaneously.

BENEFITS & SERVICES

- Rapid and accurate flexural modulus analysis of homopolymers and copolymers (Block, RACO, IMCO, etc.)

- Large sample volumes (25 mL) ensure proper representation for the most accurate results

- Non-destructive analysis

- No necessity for sample preparation

- Simple, highly repeatable analysis

- Operator independent results

- Solvent-free analysis

- Pre-loaded methods and analysis routines

- Results are fully compatible with DCS and LIMS systems

- Customized solutions for hazardous and non-hazardous zones

- Fully automated 24/7 analysis (MagModule II)

FURTHER INFORMATION

Other LexMar Global polyolefin application offerings include:

- Analysis of polypropylene (PP) homo and copolymers measuring xylene solubles content (XS), ethylene content (C2), Izod/ Charpy impact, and melt flow rate (MFR)

- Analysis of polyethylene (PE) measuring density and melt index

(MI)

In addition to the MagStation™ II and MagModule™ II LexMar Global proudly offers also the following analytical equipment:

- Electrostatic Reaction Monitoring:

- Correflow™ 5430

- Correstat™ 5410

- Correflux™ 5420