Summary

As the global polypropylene (PP) industry increasingly focuses on producing materials with tailored mechanical properties, an important chemical property is ethylene content (C2). This is a critical parameter for copolymers (copo), which include random (raco), block and impact copolymers (imco). The presence of C2 monomers disrupts the regu- lar PP polymer chains, fundamentally altering mechanical properties.

There is a strong market demand for PP copolymers because they offer superior properties for many applications, such as improved damage resistance and clarity. This demand, combined with the fact that these materials command higher market prices, makes their production more valuable. As a result, accurate measurement of C2 content is essential for both quality control and process optimization.

Traditional lab-based methods for measuring C2, such as those described in ASTM D297 or D3900, are time-consuming and require extensive sample preparation. These methods call for samples to be manually collected from the process and taken to the lab for analysis which makes them unsuitable for real-time process monitoring and optimization. Online Industrial Magnetic Resonance (IMR) has emerged as the only method capable of measuring C2 content from powders within minutes of production. This rapid monitoring allows for improved process control and product consistency, both of which are crucial for modern manufacturing. This capability is critical for PP producers to meet customer demands and increase market share. C2 is not typically measured on its own but in conjunction with other properties, such as tacticity measured via XS.

LexMar Global Inc. is the world’s leading supplier of Magneflow IMR technology for the PP industry. MagModule II analyzers provide fast, reliable, and solvent-free solutions for measuring polyolefin properties in real time.

LexMar’s Global’s IMR products, including MagStation II laboratory instruments and fully automated MagModule II online analyzers, have helped customers worldwide to improve their process capability index (CpK) by enabling real-time monitoring of resin properties.

PROCESS OPTIMIZATION

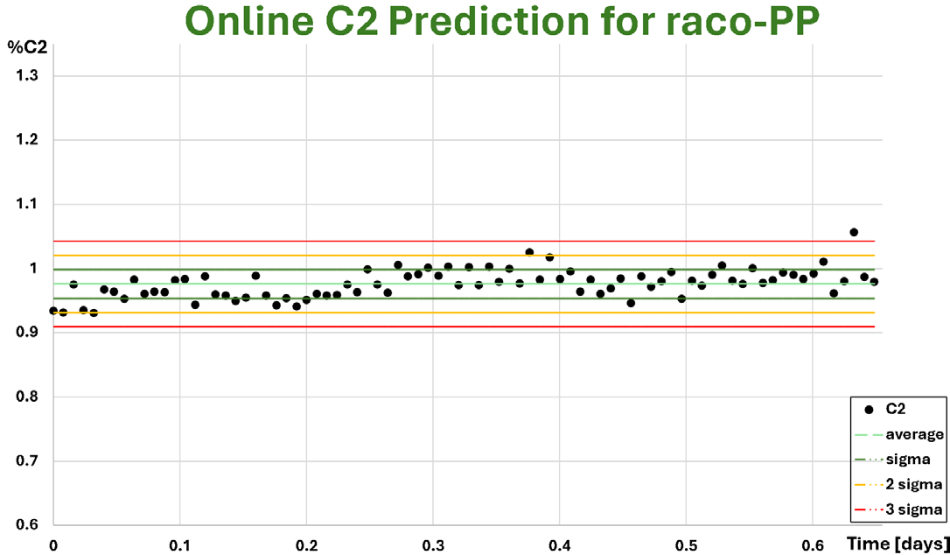

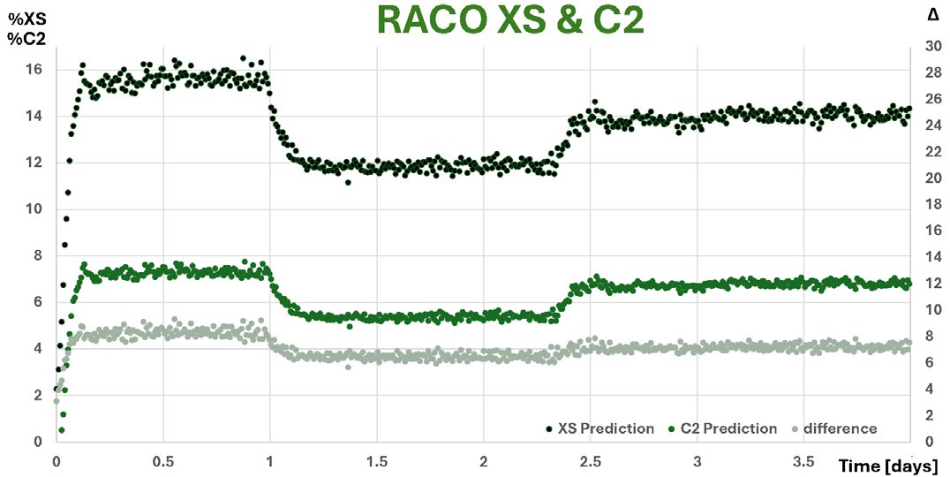

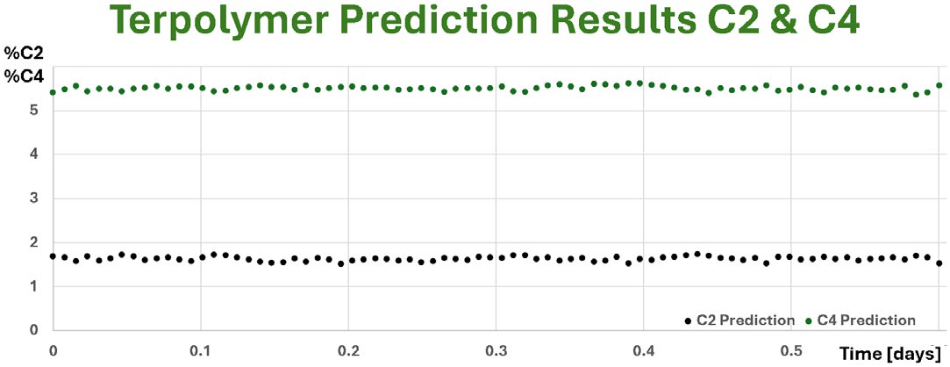

Polypropylene producers worldwide use the MagModule II online analyzer for real-time monitoring of ethylene content during PP pro- duction. This on-line instrumentation automatically collects samples from process transfer lines every 8-10 minutes, with no human intervention required. Analysis results are transmitted directly to the plant’s DCS, giving operators immediate insights into key resin properties. This rapid feedback is especially valuable during product transitions, allowing operators to quickly reach target specifications and reduce off-spec transition material. Additionally, the system enables fast intervention of process upsets, minimizing downtime and pro- duct loss. Ultimately, the advanced real-time control provided by the MagModule II improves reactor performance, leading to lower production costs and optimized polymer materials.

Quality Control

The MagStation II is a laboratory IMR analyzer used for quality control which can measure both powders and pellets. This semi-automatic instrument provides insights into reactor grades and finished products and can be integrated with a LIMS (Laboratory Information Management System). This allows for product release and the generation of Certificates of Analysis (CofA). The instrument is delivered either with a single stage sampler or a 15-position carousel which allows for overnight runs.

Calibration and Analysis

IMR analyzers are calibrated against traditional wet laboratory methods, either by LexMar Global or by trained plant staff. While raco, block and imco copolymers require separate calibrations due to their unique chemical structures, this tailored approach ensures a highly precise and accurate analysis for each material.

The IMR method uses advanced multivariate principal component analysis (PCA) and partial least squares (PLS) techniques to create ro- bust calibration models. These models, which incorporate multiple product grades, remain stable for years and can be used effectively during product transitions. A key benefit of the method is that analy- sis is virtually unaffected by a sample’s color, particle size, or homo- geneity because IMR technology measures the bulk morphology of the material, not just surface composition. This ensures the analysis is accurate and consistent, as demonstrated by the excellent repeata- bility of the IMR method. Magneflow products can be used to analyze a variety of sample forms, including film, pellets, and powders. The IMR method can benefit any PP process technology.

Sampling

For online analysis, the MagModule II system uses a customized sample extraction panel that automatically collects samples directly from the production line, as close to the reactor as possible. This pro- cess is fully automated and operates around the clock 24/7, providing real-time, continuous measurements of the resins’ properties. A key advantage of this system is that it handles all sample sizing and preparation automatically, delivering operator-independent results. Since the entire sample is returned to the process after analysis, resin waste is eliminated. This approach is available in custom solutions for both hazardous and non-hazardous locations.

For offline laboratory analysis, the MagStation II offers a simple and highly repeatable solution. It requires no sample preparation. The purpose made software features pre-loaded methods and analysis routines which make operation extremely easy.

BENEFITS & SERVICES

- Rapid and accurate C2 analysis of polypropylene copolymers

- IMR can measure multiple PP properties simultaneously

- Large sample volumes ensure proper representation for the most accurate results

- Simple, highly repeatable analysis

- Operator independent results

- No manual sample conditioning required

- Fully automated 24/7 analysis (MagModule II)

- Non-destructive, solvent-free analysis

- Pre-loaded methods and analysis routines

- Results are fully compatible with DCS or LIMS systems

- Customized solutions for hazardous and non-hazardous zones

- Improves plant efficiency and reduces off-spec production

- Compatible with Advanced Process Control (APC) systems

- Low total cost of ownership

Further Information

Other LexMar Global polyolefin application offerings include:

- Analysis of polypropylene (PP) homo and copolymers measuring xylene solubles content (XS), Flexural Modulus (FM), Izod/ Charpy impact, and melt flow rate

- Analysis of polyethylene (PE) measuring density and melt index

In addition to the MagStation™ II and MagModule™ II LexMar Global proudly offers also the following analytical equipment:

- Electrostatic Reaction Monitoring:

- Correstat™ 5410

- Correflux™ 5420

- Correflow™ 5430