SUMMARY

Particulate carryover in gas phase recycle lines is a persistent challenge in polyolefin reactor control. Excess entrained particles can foul heat exchangers, pumps, and distributor plates, leading to reduced cooling efficiency, unplanned shutdowns, and costly maintenance. Fines carryover can disrupt fluidization stability, degrade product quality, and damage down-stream equipment.

Polyolefin reactions are exothermic, releasing large amounts of thermal energy, and the rate of production is limited by how effectively heat is removed. Cooling is achieved by circulating the fluidizing gas through a recycle loop containing a heat exchanger. Increasing recycle gas flow enhances heat removal, enabling higher production rates. However, when flow rates are pushed beyond critical limits, polymer particles can be carried out of reactors and into recycle lines.

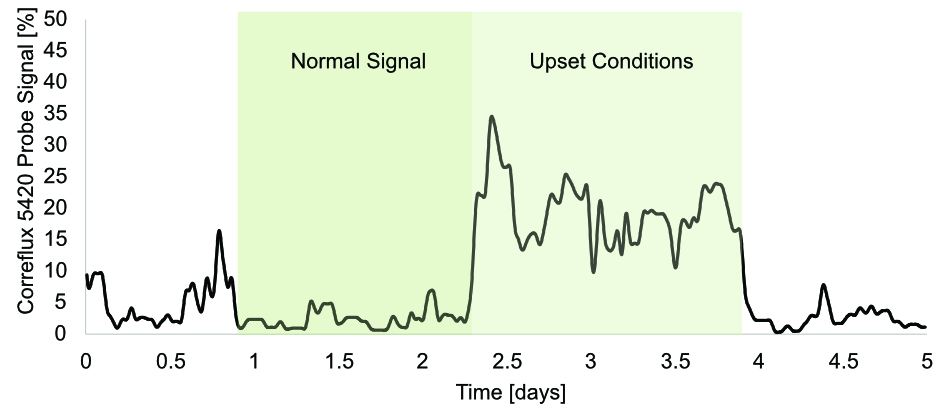

The Correflux™ 5420 carryover electrostatic probe provides real-time monitoring of entrained particles, allowing operators to detect changes in carryover dynamics and adjust process parameters to maintain stable operations, protect equipment, and optimize production rates.

Technology Overview

The Correflux 5420 detects entrained particles in gas recycle and discharge lines by measuring the triboelectric current generated when particles impact its sensing surface. As particles impact the probe tip, they transfer a small amount of electrical charge. Particle flow characteristics such as mass flow, particle size, and velocity determine how often particles strike the probe and how much charge is transferred per impact. This charge transfer produces a low-level current directly proportional to the relative amount of particulate contacting the probe which enables detection of process upset conditions as they arise.

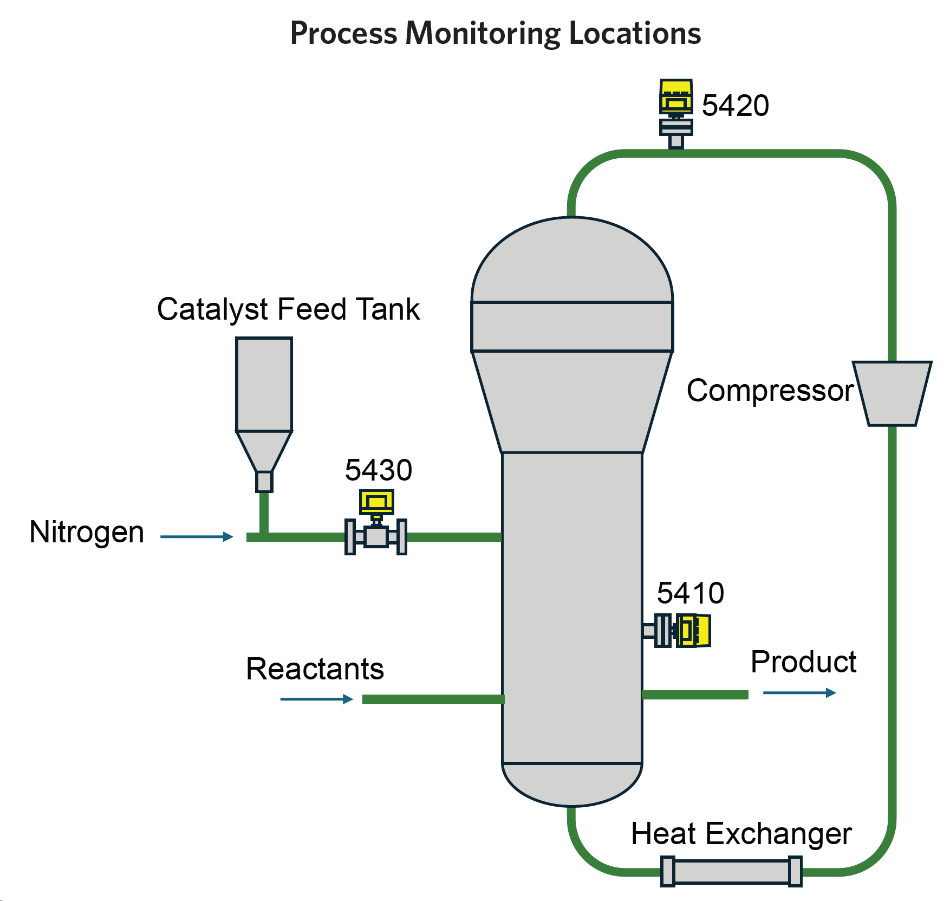

Process Locations

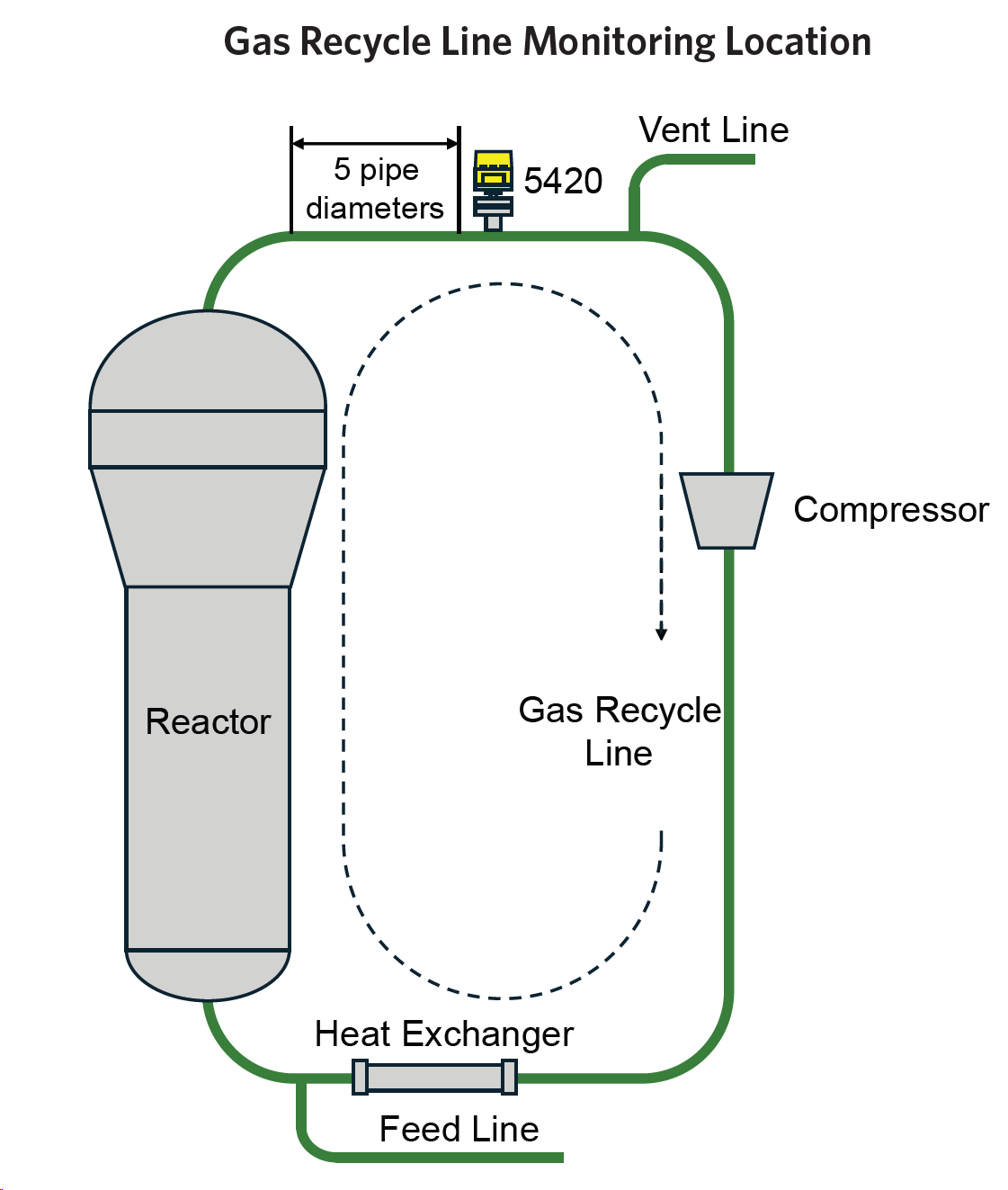

The Correflux 5420 is typically installed in gas recycle lines, discharge lines, or other high-velocity sections where entrained particles are likely to be carried out of the reactor. These points provide early indication of changes in particulate loading, often before visible fouling or downstream equipment issues occur. Placement upstream of heat exchangers and compressors allows operators to take corrective action before costly damage or efficiency losses develop. The probe’s rugged, flange-mounted design allows straightforward integration into existing access ports, ensuring minimal installation downtime. Field experience has shown that installations close to the reactor outlet but

at least five pipe diameters from an elbow produce the best results. Its rugged design withstands harsh reactor discharge environments, and customizable probe configurations ensure straightforward installation into pre-existing 1″ – 4″ nozzles.

Data and Interpretation

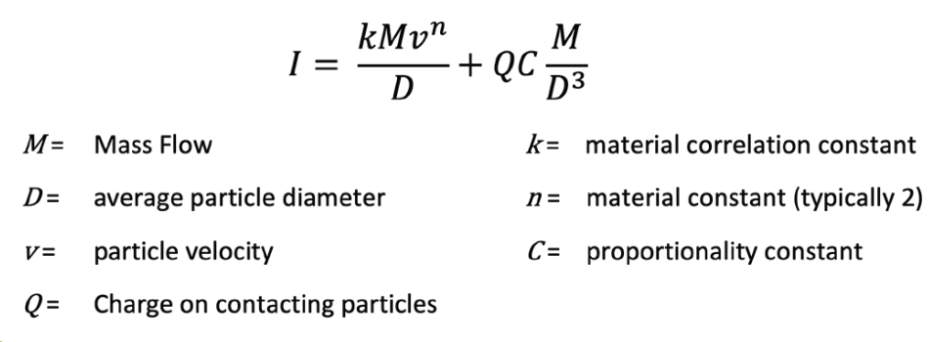

The current (I) measured by the Correflux™ 5420 probe can be described by the following equation:

The first term represents the current generated by the triboelectric effect. In this term, particle velocity has a strong influence, often more than mass or size, because the rate of collisions and the energy of each contact both increase with particle velocity.

The second term accounts for the contribution of any pre-existing charge on impinging particles. Here, the particle’s physical characteristics, especially its size, play a significant role. Smaller particles have a higher surface area-to-volume ratio and can carry proportionally more charge.

Reactor Influence on Carryover

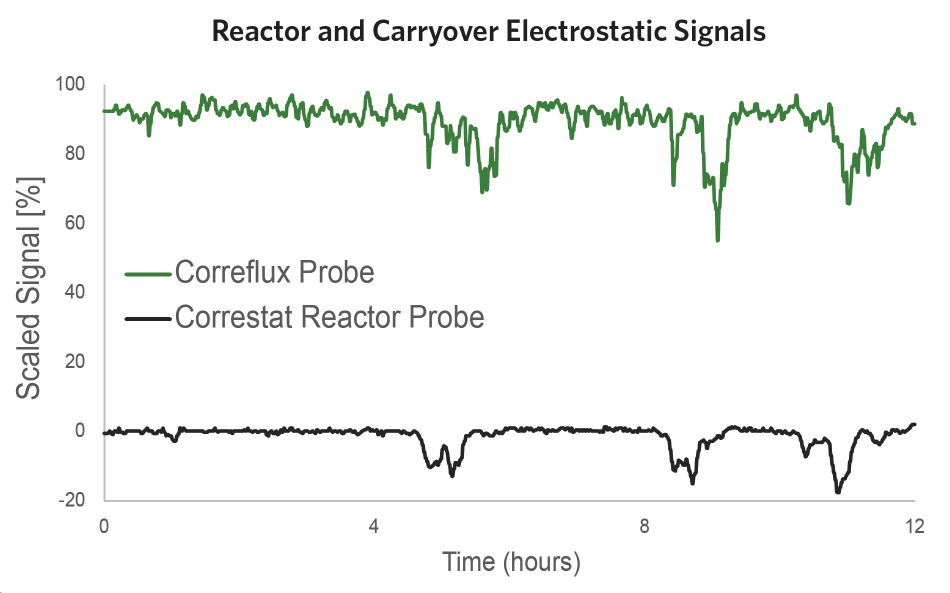

Reactor conditions directly shape how fines are generated and whether they are carried into recycle lines. Research shows that electrostatic forces in reactor beds influence carryover by causing fines to repel one another or cluster with larger particles and remain in the bed. These effects can either increase or decrease carryover, depending on charge conditions, and ultimately govern whether fines are inhibited or allowed to pass into the recycle stream. By combining reactor electrostatic activity monitoring [Correstat 5410] with entrained particulate monitoring [Correflux 5420], operators can gain deeper process insight to better anticipate when fines production and entrained particle carryover are likely to rise.

Key Application Considerations

- Hazardous location rated equipment ensures safe, compliant operation in classified reactor environments.

- Custom-designed probes allow straightforward, low-cost installation into existing ports and nozzles.

- Optimized sensor placement provides maximum process feedback and early detection of particle entrainment.

- Real-time monitoring of carryover enables dynamic adjustments to process conditions to optimize reactor production rates and avoid fowling of downstream equipment.

- Wide sensitivity range (pA to μA) delivers reliable detection across a diverse range of operating conditions.

- Real-time local display and 4-20mA output of multiple process parameters empower DCS control room decisions.

Product Lines

Electrostatic Reaction Monitors

- Correstat™ 5410—Electrostatic Charge Imbalance Monitoring

- Correflux™ 5420—Entrained Particle Carryover Detection

- Correflow™ 5430—Catalyst Feed System Monitoring

Industrial Magnetic Resonance (IMR) Analyzers

- MagStation™ II (laboratory)

- MagModule™ II (online)

Analysis of polypropylene and polyethylene key polymer properties.