SUMMARY

Gas phase fluidized bed polyolefin reactors are prone to electrostatic charge buildup, which can cause particle

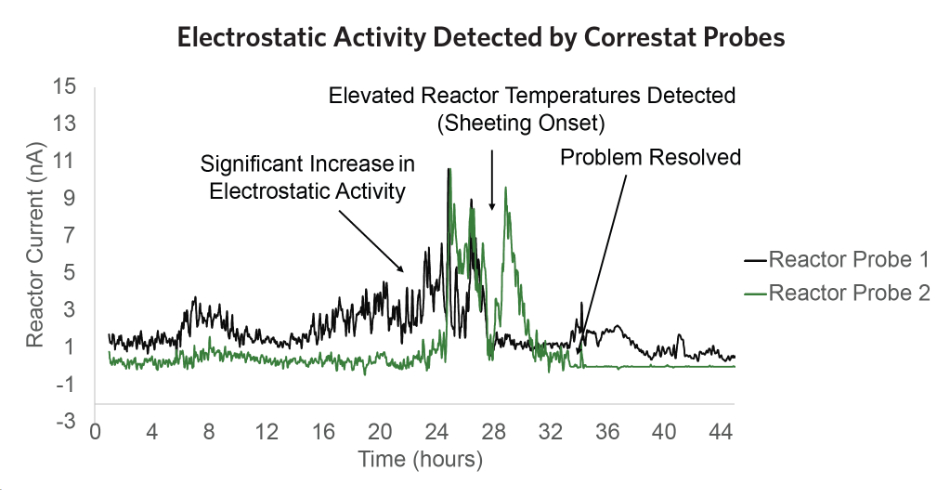

agglomeration, resin sheeting/fouling on the distributor plate and reactor walls, quality problems, and unplanned shutdowns that are both operationally disruptive and costly. Because electrostatic charging is inevitable whenever particulates are fluidized or pneumatically transferred from one location to another, monitoring is essential. Research has shown a strong correlation between excess electrostatic charge and the onset of sheeting. Once particles adhere to the reactor wall, they can overheat and fuse, leading to severe process disruptions and expensive maintenance.

The Correstat™5410 is the only electrostatic sensor that provides real-time, bipolar current measurements of electrostatic charge imbalances within the reactor. By detecting deviations in charge levels early, well before wall temperature anomalies or product quality issues arise, operators can take corrective action to maintain continuous, stable operation.

Technology Overview

In a gas phase fluidized bed reactor, solid particles are constantly moving, colliding, and sliding past each other and the walls of the reactor, transferring charge through the triboelectric effect; the

phenomenon where contact and separation result in one surface becoming positively charged and the other negatively charged.

Charge generation is dependent on the following factors:

- Material composition (polymer type, catalyst, additives)

- Particle size distribution

- Bed dynamics (bubble size, gas velocity, circulation patterns)

- Environmental factors (humidity, impurities, antistatic agents)

As charge builds up, electrostatic potential imbalances form between different regions of the bed and reactor walls. When the attractive electrostatic force overcomes the forces from fluidization, particles can adhere to walls.

The Correstat 5410 probe detects these charge imbalances in real time by measuring the tiny currents induced or transferred by charged polymer particles. Unlike traditional probes that measure voltage (often thousands of volts), the 5410 uses a current measurement approach with the probe tip maintained at less than 1V. This allows it to detect bipolar charge activity safely, continuously, and with a wide range of sensitivity (from picoamps to microamps). When positioned at locations prone to sheeting, plant operators can observe when electrostatic activity begins to shift outside normal patterns—often hours before the first signs of sheeting appear in wall temperature profiles. This early detection enables corrective actions such as adjusting catalyst feed rates, changing gas velocities, or injecting antistatic agents.

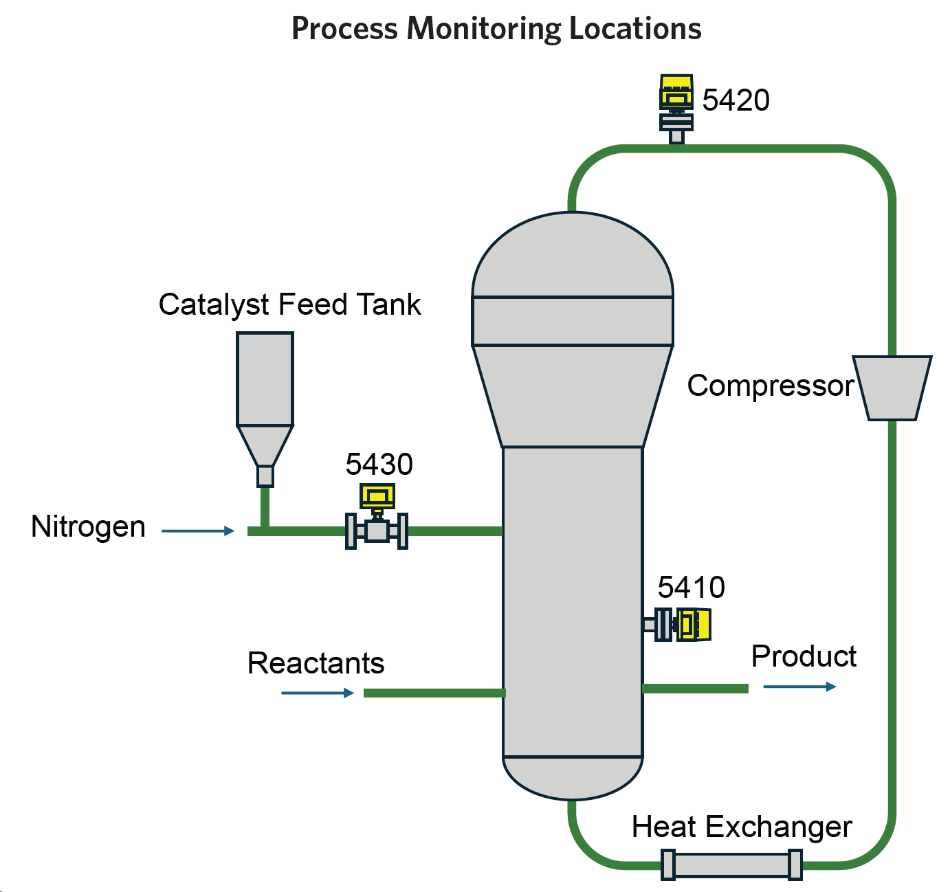

Process Locations

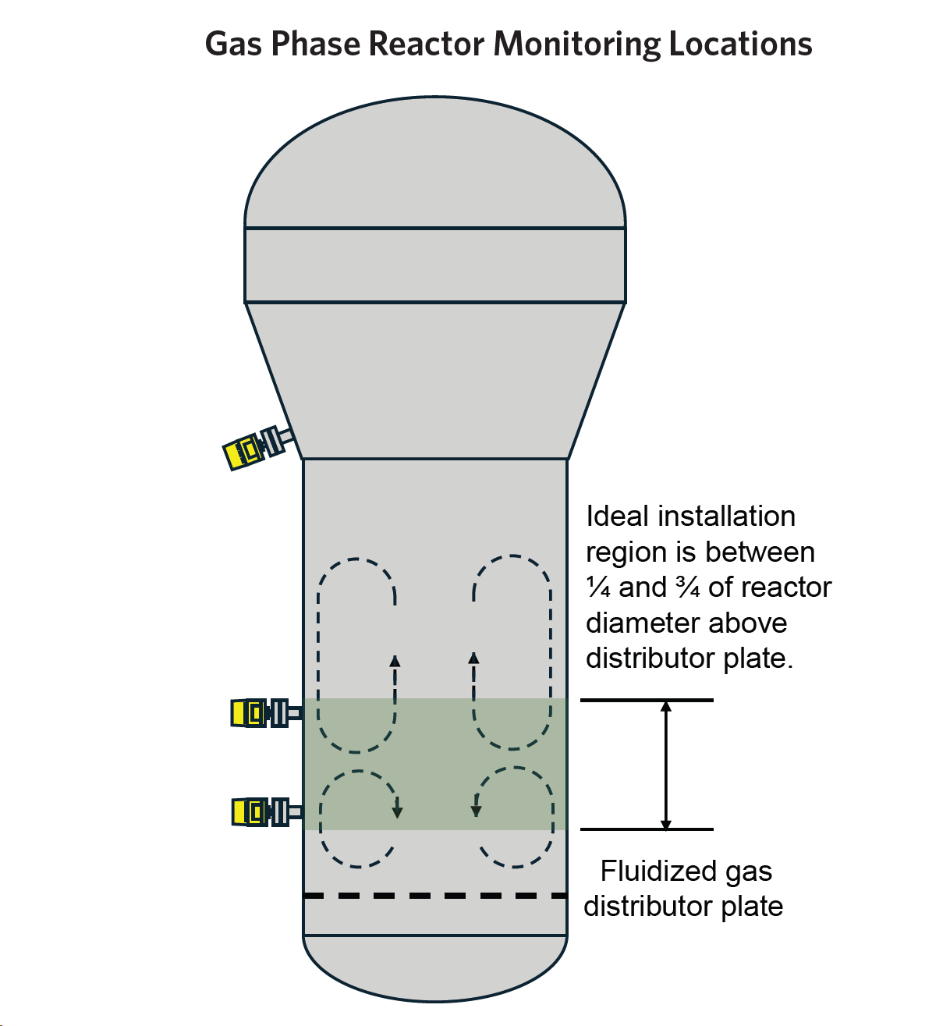

Sheeting events can occur on the interior walls, expansion sections, or dome of reactors. To maximize the chance of detection, it is suggested that Correstat 5410 probes should be installed in the locations shown in Figure 1. This multi-location approach provides plant operators with more complete coverage, enabling faster response to mitigate process upsets.

In fluidized beds, wall sheet formation is commonly observed at an elevation between 1/4 and 3/4 of the reactor diameter above the fluidization gas distributor plate. This region is often a stagnation zone where particle velocities are low. (Hendrickson, 2006) Placement of sensors in this zone improves sensitivity to early- stage sheet formation before large accumulations develop.

Hendrickson, G. Electrostatics and Gas Phase Fluidized Bed Polymerization Reactor Wall Sheeting. Chem. Eng. Sci. 2006, 61 (4), 1041–1064.

Data and Interpretation

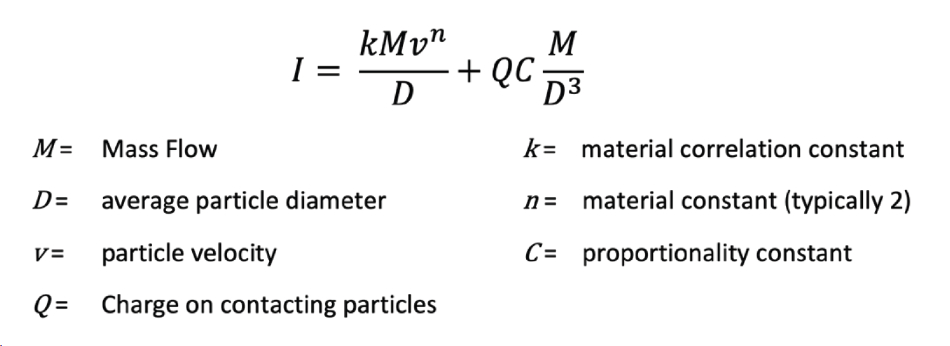

The current (I) measured by the Correstat 5410 probe can be described by the following semi-empirical equation:

The first term represents the current generated by the tribo-electric effect. In this term, particle velocity has a strong influence, often more than mass or size, because the rate of collisions and the energy of each contact both increase with velocity.

The second term accounts for the contribution of any pre-existing charge on impinging particles. Here, the particle’s physical characteristics, especially its size, play a significant role. Smaller particles have a much higher surface area to volume ratio, can carry proportionally higher specific charge, and may carry the opposite charge polarity as their larger counterparts. In most fluidized bed reactors, the particle velocities are low so pre- existing charge from particulate to the probe surface will be the major contributor to the measured current.

Current Vs. Voltage Measurements

In earlier methods, reactor probes measured bed potential

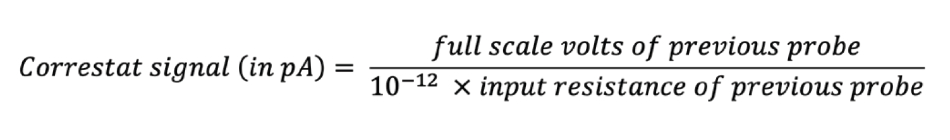

as a voltage. The Correstat 5410 probes instead measure current flowing from the bed through the probe to ground, which is insensitive to probe input resistance, for a more direct representation of electrostatic activity. For compatibility with older systems, voltage measurement ranges can be converted to an equivalent current measurement range using Ohm’s Law:

Key Application Considerations

- Hazardous location rated equipment ensures safe, compliant operation in classified reactor environments. No nitrogen purge required.

- Custom-designed probes allow straightforward, low-cost installation into existing ports and nozzles.

- Optimized sensor placement provides maximum process feedback and early visibility of charge imbalances.

- Real-time monitoring of charge buildup enables proactive avoidance of shutdowns from sheeting or agglomeration events.

- Wide sensitivity range (pA to μA) delivers reliable detection across diverse operating conditions.

- Real-time local display and 4-20mA output of multiple process parameters empower DCS control room decisions.

Product Lines

Electrostatic Reaction Monitors

- Correstat™ 5410—Electrostatic Charge Imbalance Monitoring

- Correflux™ 5420—Entrained Particle Carryover Detection

- Correflow™ 5430—Catalyst Feed System Monitoring

Industrial Magnetic Resonance (IMR) Analyzers

- MagStation™ II (laboratory)

- MagModule™ II (online)

Analysis of polypropylene and polyethylene key polymer properties.