PROCESS CONTROL USING INDUSTRIAL MAGNETIC RESONANCE (IMR)

Polypropylene (PP) has become the material of choice for a wide range of applications, supplanting traditional materials such as steel, ceramics, and wood. In response to escalating demands for perfor- mance and customization, the global PP industry is undergoing a technological transformation to enhance production efficiency, shor- ten production cycles, and create tailored products for a large variety of applications.

The plant operators monitor several key engineering properties to ensure that product grades are within specifications. Since even the best advanced process control (APC) technology still requires feed- back for these key polymer properties to optimize process settings, this is typically done using IMR, which is a well-proven method and has been used for several decades in the industry.

As the world’s premier provider of IMR technology, LexMar Global offers robust analyzers tailormade for the PP industries’ needs. The MagStation™ II laboratory instrument and MagModule™ II online process analyzer are industry standards used by top polyolefin resin producers worldwide.

For process control, PP manufacturers typi- cally measure Xylene Solubles (XS) content close to the reactor on powders, typically in the hazardous area of the plant. Please see the LexMar Global XS application note for details about process control and optimization as well as for a description of the IMR technology.

MECHANICAL PROPERTIES

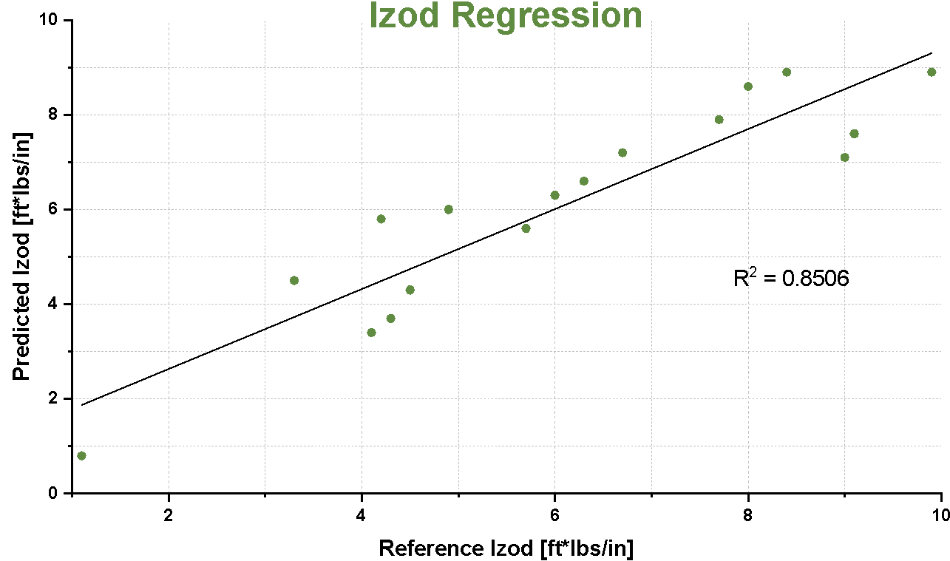

Impact strength, i.e., a polyolefin’s ability to resist a sudden, forceful blow is traditionally measured according to the Charpy impact test or the Izod pendulum impact resistance of plastics according to ISO (ISO 180-Izod, ISO 179-Charpy) or ASTM (D256-Izod, D6110-Charpy) test methods, respectively. However, these methods are very time- consuming, require the preparation of multiple test specimens, are prone to errors due to operator dependencies, require repeated analysis for accurate results which means the traditional methods present bottlenecks for lot release. Additionally, these tests are also known to be extremely sensitive to small experimental changes and have relatively large test errors around 1 kJ/m2.

Magneflow Industrial Magnetic Resonance from LexMar Global can be used to determine mechanical properties such as Charpy, Izod, or Flex Modulus simultaneously within 15 minutes.

PP is often copolymerized to enhance impact properties. Monitoring these properties immediately after extrusion allows producers to maintain strict quality control. Online NMR systems provide real- time quality assurance by identifying off-spec materials based on mechanical properties, enabling continuous process optimization.

Traditionally, mechanical analysis occurs hours to days after extru- sion of the final pelletized product, but modern customer demands require consistent proof of quality. To meet these quality standards, polypropylene producers instead rely on IMR online analyzers to continuously track impact strength throughout the extrusion and pelletization process.

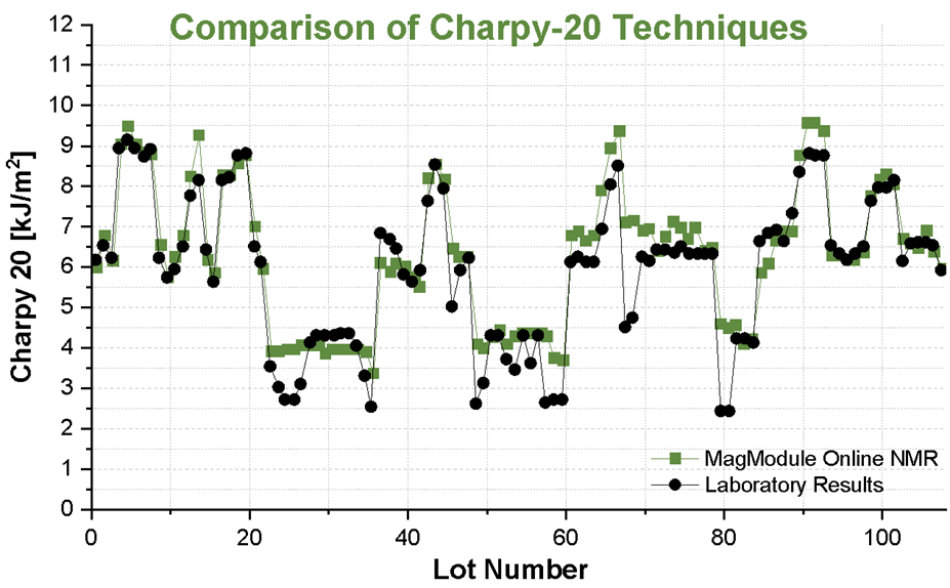

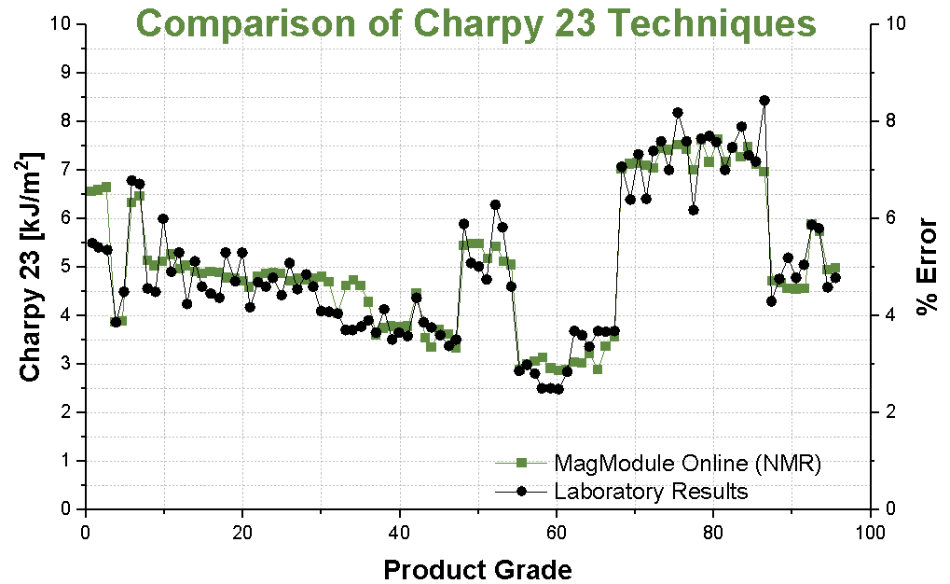

IMPACT STRENGTH MONITORING ONLINE AND IN THE LABORATOR

The MagModule II online analyzer enables 24/7 measurements, pro- viding up to six analyses per hour. This real-time monitoring allows for immediate lot release and can save up to $400k per line per month depending on process configurations. If off-spec material is detected, it can be diverted to an intermediate silo, preventing pro- duction and shipment delays. The MagStation II, a laboratory ver- sion, offers less frequent manual sampling but still enables near real- time product release and significant time savings by eliminating the need for lengthy sample preparation.

CALIBRATION AND RESULTS

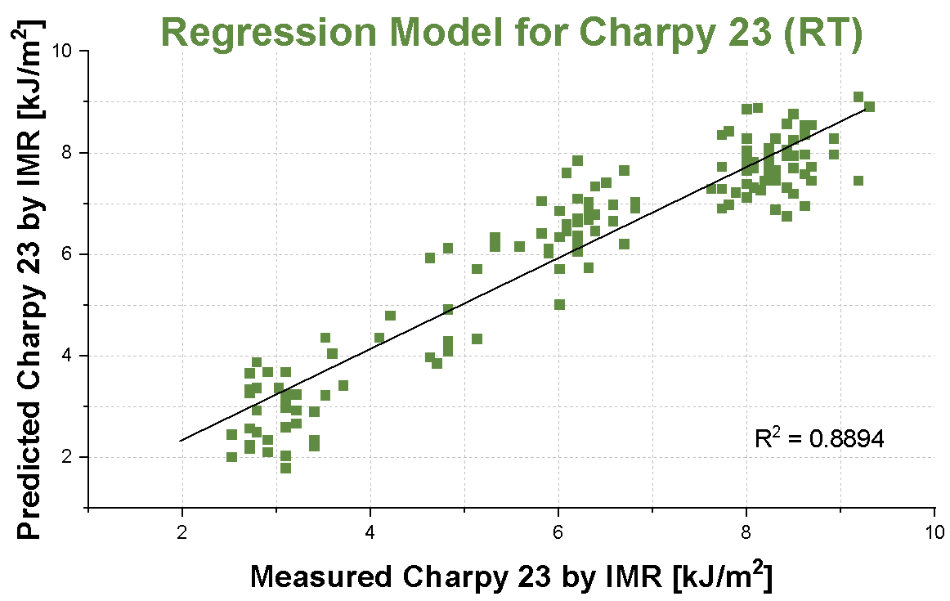

IMR analyzers are typically calibrated against traditional standard methods. It is the customer’s choice whether the calibration is per- formed by LexMar Global or locally by the plant staff. The use of multivariate PCA and PLS techniques enables the generation of ro- bust calibration models. For mechanical properties it is recommen- ded to use many reference datapoints, ideally performed by expe- rienced operators – especially in the case of tests involving notched plaques. Once these models are established, they are very stable, ty- pically for years. Fig. 3 and 4 demonstrate typical calibration perfor- mances for the Magneflow product line.

BENEFITS & SERVICES

- Real-time lot release by production, resulting in a reduction in inventory and substantial savings

- Reduction of off-spec production due to early intervention (first time right production of prime material)

- Reduction of silo storage requirements

- Rapid analysis of impact strength for precise characterization of PP homo- and copolymers (random, impact, block etc.) within minutes

- A final blend impact strength value can be statistically calculated based on weighted average of the continuous online IMR measurements, not measured once per lot

- No sample preparation required

- Large sample volumes ensure proper sample representation for the most accurate results

- Seamless integration with DCS and LIMS systems

- Non-destructive solvent-free analysis with no wasted product

FURTHER INFORMATION

In addition to the analysis of impact properties, Magneflow analyzers are capable of measuring Xylene Solubles content, Ethylene Content, and Flexural Modulus.

In addition to the MagStation™ II and MagModule™ II LexMar Global proudly offers also electrostatic monitoring equipment such as Correstat™ 5410, Correflux™ 5420, and Correflow™ 5430.