SUMMARY

Gas-phase polyolefin reactors typically rely on lock-hopper systems or rotary feeder mechanisms to meter chromium/silica, Ziegler–Natta, or metallocene catalysts into a carrier-gas stream that conveys them to the reactor. Feeding anomalies such as irregular pulses, partial blockages, blow-through, shot-to-shot timing drift, and shifts in flowability (clumping or fragmentation) can lead to production rate swings, cause product quality drift, and in extreme cases, trigger electrostatic issues in the reactor.

Because many reactors have long residence times feedback and adjustment require a delicate balance. If process adjustments are made with incomplete information, overcorrection is likely to occur before the reactor bed responds. To avoid these problems, real-time catalyst feed monitoring is essential. Real- time monitoring lets operators identify emerging faults early, distinguish feeder issues from reactor issues, and intervene before minor disturbances grow into reactor upsets.

With clearer insight into catalyst feed dynamics, plants can achieve tighter process control, better continuity through transitions, and have fewer quality excursions, thus reducing off- spec production.

Technology Overview

Catalyst particles become electrically charged when they rub against pipes, tumble in the carrier gas, or collide with other particles. This charge transfer is due to the triboelectric effect, which involves the exchange of electrons during contact and separation of materials. The magnitude and sign of charge is governed by factors such as dissimilar material pairings, impact velocity, particle size, surface roughness, humidity, and pre- existing charge on surfaces. Sensitive electrostatic sensors exploit this effect for monitoring. As a charged catalyst pulse passes through a sensing electrode, a small current is measured. Under steady conditions, the magnitude of this current is proportional to the number of particles and the charge they carry. By monitoring these current signals operators can gain insight into catalyst flow characteristics, detect feeder faults (e.g., partial blockage or blow- through), and recognize electrostatic signatures characteristic of specific catalysts (such as metallocenes). These measurements qualitatively reveal how much catalyst is entering, charging dynamics, and when delivery deviates from expected normal conditions, enabling timely operator intervention.

The Correflow™ 5430 Catalyst Feed monitor by LexMar Global is an electrostatic ring sensor designed for use on catalyst feed lines. Custom sensor bodies are precision engineered to match existing line diameters, ensuring seamless installation and avoiding any restrictions that would upset flow characteristics. These sensors are engineered to detect extremely small amounts of catalyst and are more sensitive than traditional differential pressure measurements.

Case Study

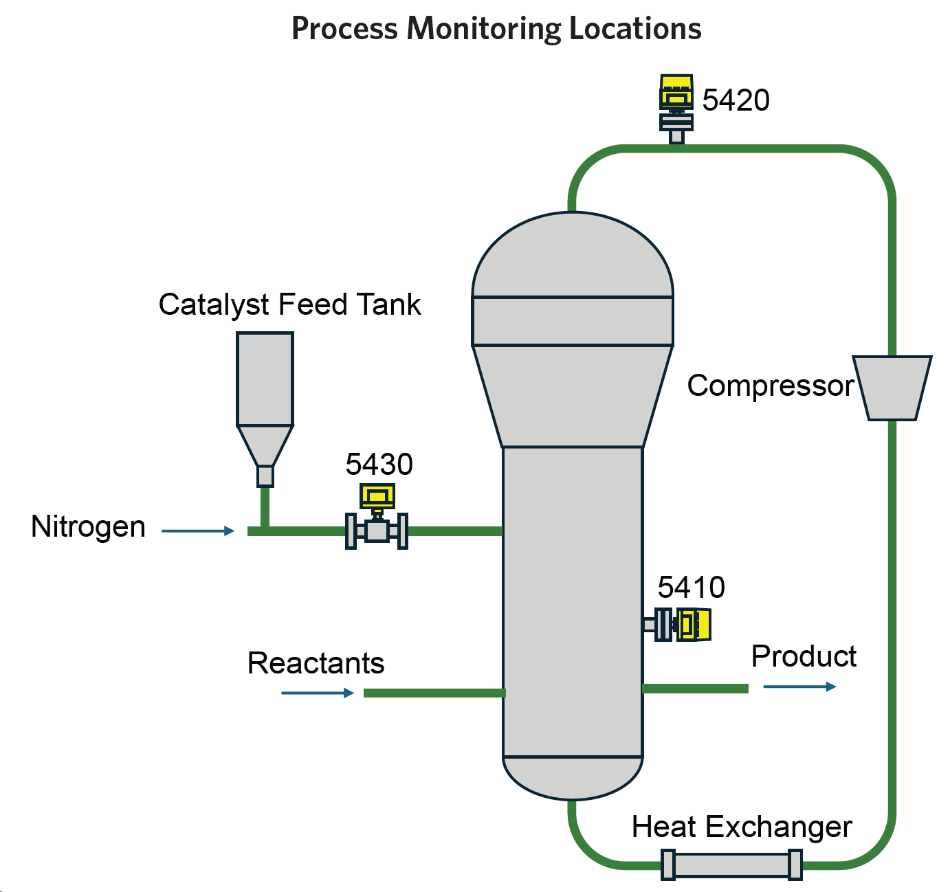

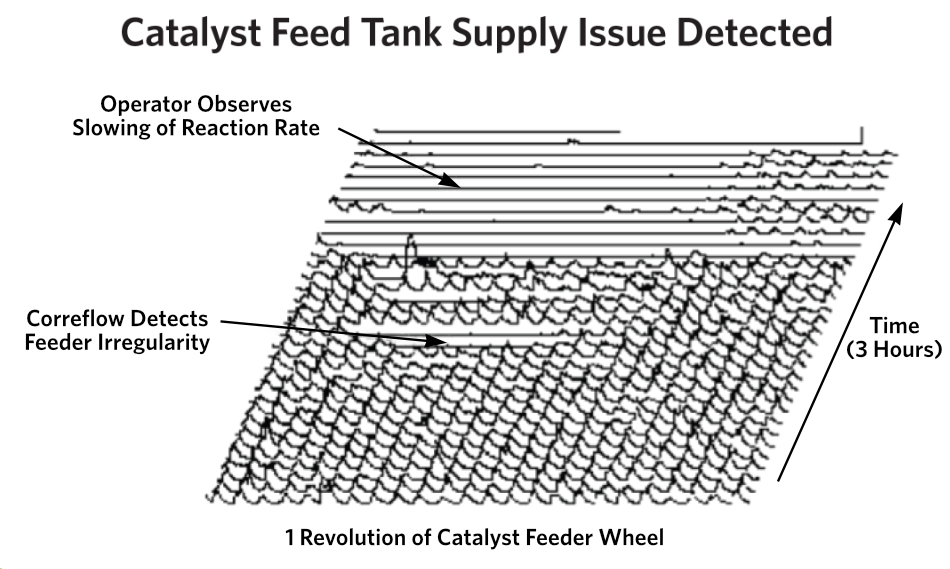

Many gas-phase polyolefin reactors utilize a multiport rotary catalyst feeder mechanism that periodically dispenses catalyst portions into a gas feed line which is then conveyed to the reactor. The data below is from a Correflow sensor installed on such

a gas feed line. In this installation, the sensor detected abrupt and inconsistent feeder behavior as the tank ran empty. This information provided a roughly 35-minute early warning prior to operators observing a decrease in reactor production rate.

Interpretation of Signal Patterns

In steady state operation, catalyst shots should appear as uniform, periodic pulses with consistent amplitude and width. The between-shot baseline should be flat, indicating no unintended flow. From installation onward, operators should aim to learn and recognize characteristic patterns to easily distinguish feeder fault signatures. Common feeder fault signatures include:

- Empty feeder tank: increased variance as the catalyst level drops followed by extended periods of no detected pulses.

- Clogged cavity or partial blockages: periodic low amplitude pulses (every nth shot).

- Blow-through / leakage between index positions: measurable baseline flow between shots or small “shoulder” pulses between main peaks.

- Timing drift and feeder wear: a gradual shift in pulse phase vs. index signal; widening or narrowing shot-to-shot spacing.

- Flowability changes (clumping or breakup): inconsistent peak widths often accompanied by trailing tails; may coincide with humidity or material change.

- Polarity anomalies: sign flips or abrupt magnitude changes after maintenance, catalyst switch, or upstream line changes—check grounding and pre-charge.

Catalyst Dosing Effect on the Reactor

Catalyst feed accuracy (amount) and catalyst charge (polarity) impacts both reaction kinetics and electrostatic activity.

Catalyst dosing effects on bed chemistry

Catalyst feed rate directly governs reaction kinetics and heat release. Underdosing reduces the number of active sites, lowering product yield. Overdosing raises site density and local heat release. These hotter zones accelerate early polymer growth while particles are still mechanically weak, which increases fragmentation risk, redistributes solids, and can decrease product quality. Because gas-phase beds typically have long residence times, any rate shifts resulting from improper catalyst dosing may appear well after disturbances, increasing the risk of over-adjustment. In practice, smoother feed profiles and prompt detection of shot-to-shot variability help maintain steady polymerization and minimize off-spec production.

Catalyst dosing effects on bed electrostatics

Upon entering the bed, charged catalyst particles can be attracted to grounded metal surfaces, promoting wall adhesion and, ultimately, sheeting. Overdosing can intensify particle– particle and particle–wall contacts, elevating charge generation within the bed.

However, when catalyst which is oppositely charged compared to the bed enters the reactor, electrostatic forces are reduced or neutralized. Carryover of small particles can increase, since charge no longer helps fines remain attached to larger granules in the bed. The net electrostatic state of the reactor is therefore sensitive to both the charge carried by the catalyst dose and the

way the dose perturbs collisions in the bed.

Key Application Considerations

- Hazardous location rated equipment ensures safe, compliant operation in classified reactor environments.

- Custom-designed sensors allow straightforward, low-cost installation into existing lines with no increased pressure drop or restrictions.

- Real-time monitoring of catalyst feed enables proactive intervention before small disturbances grow into reactor upsets

- Wide sensitivity range (pA to μA) delivers reliable detection across diverse operating conditions.

- Real-time local display and 4-20mA output of multiple process parameters empower DCS control room decisions.

Product Lines

Electrostatic Reaction Monitors

- Correstat™ 5410—Electrostatic Charge Imbalance Monitoring

- Correflux™ 5420—Entrained Particle Carryover Detection

- Correflow™ 5430—Catalyst Feed System Monitoring

Industrial Magnetic Resonance (IMR) Analyzers

- MagStation™ II (laboratory)

- MagModule™ II (online)

Analysis of polypropylene and polyethylene key polymer properties.